Comprehensive Beam Yard Supply Solution

Comprehensive Beam Yard Supply Solution by Hunan Wuxin Intelligence Technology Co., Ltd.

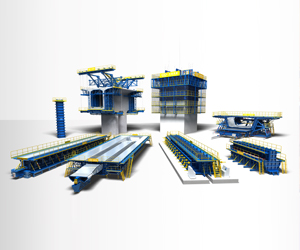

With the continuous expansion of high-speed railway and large-scale bridge construction, beam yards—where precast box girders are produced and managed—play a crucial role in project progress, quality control, and construction safety. Based on years of expertise in the design and manufacturing of bridge construction equipment, Wuxin Intelligent Technology Co., Ltd. provides a systematic, standardized, and replicable “Comprehensive Beam Yard Supply Solution” for railway, highway, municipal, and major cross-sea/cross-river bridge projects. This solution delivers a one-stop, turnkey construction package that ensures efficiency, sustainability, intelligence, and full controllability.

I. Company Advantages

Hunan Wuxin Intelligence Technology Co., Ltd. is a leading supplier of bridge construction equipment systems in China, specializing in the design and production of box girder formwork, segmental girder formwork, cantilever form travellers, movable scaffolding systems, casting yard pedestal systems, gantry cranes, and intelligent beam yard management systems.

Key advantages include:

Independent R&D and Engineering Team capable of customized solutions based on route conditions and girder types;

National-level Production Base with an annual steel equipment manufacturing capacity exceeding 80,000 tons;

Global Project Experience, with equipment exported to many major overseas projects;

Comprehensive After-sales Support, including onsite technical assistance and maintenance services.

II. Components of the Comprehensive Beam Yard Solution

The solution follows the principles of integrated planning, system engineering, phased implementation, international delivery, and long-term service support, covering the entire beam yard life cycle from planning to production.

1. Beam Yard Layout and Planning

Site selection and facility arrangement based on bridge alignment and transportation conditions;

Overall layout design for casting pedestals, track lines, rebar processing zones, concrete batching stations, etc.;

Design of utilities distribution, logistics pathways, and material flow systems.

2. Formwork and Casting Equipment Supply

| Equipment Type | Key Components | Features |

|---|---|---|

| Box Girder Formwork System | Side mold, bottom mold, inner mold, end mold | High stiffness, precise assembly, excellent concrete finish |

| Segmental Girder Formwork | U-shape, box-shape, T-shape, special profiles | Modular design, suitable for balanced cantilever construction |

| Casting Pedestal and Rail System | Standard / adjustable pedestals | Accommodates multiple girder types, ensures casting stability |

| Intelligent Tensioning and Grouting System | Data-controlled, traceable tensioning and grouting | Improves quality control and construction reliability |

3. Auxiliary Construction Equipment

Beam yard gantry cranes and overhead traveling cranes;

Segment erection and assembly jigs;

Concrete curing systems (steam heating / electric / thermal insulation options).

4. Digital and Intelligent Control Systems

MES-based girder production management system;

Quality monitoring and traceability platform;

Equipment operation and maintenance monitoring;

Smart logistics and safety control system.

These enable digitalized, visualized, and fully traceable production operations.

III. Service Model

| Project Stage | Service Scope | Deliverable |

|---|---|---|

| Pre-Consultation | Site survey, technical communication, conceptual design | Beam yard planning report |

| Equipment Delivery | Formwork, pedestals, cranes, transport equipment | Factory inspection & delivery documents |

| Onsite Installation & Commissioning | Technical team onsite guidance and trial production | Acceptance and handover |

| Production Support | Operator training, quality supervision, equipment maintenance | Long-term support or stationed service |

| Project Completion | Equipment dismantling and relocation proposals | Reuse and relocation plan provided |

IV. Implementation Benefits

Construction period reduced by 15%–30%

Dimensional accuracy controlled within ±2 mm

Logistics efficiency improved by approximately 40%

Reduced labor dependency and improved management transparency

V. Representative Projects

Wuxin has successfully supplied comprehensive beam yard systems to numerous major infrastructure projects, including:

Beijing–Shanghai High-Speed Railway

Chengdu–Chongqing High-Speed Railway

Jakarta–Bandung High-Speed Railway (Indonesia)

The solution is mature, reliable, and proven in international applications.

VI. Conclusion

Wuxin’s Comprehensive Beam Yard Supply Solution, featuring integrated system engineering, digital intelligence, and full-cycle services, enables safe, high-quality, efficient, economical, and controllable girder production. We look forward to cooperating with global partners to jointly advance world-class transportation infrastructure construction.